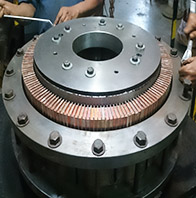

Commutator is very critical component in DC Motors and requires very stringent process with monitoring at every stage of manufacturing. At Raut Electro-Mech Commutators are manufactured as per customers Specifications / Drawings.

| Industrial Commutators | Molded Commutators |

Industrial Commutators

Industrial Commutator manufacturing involves following stages -

Molded Commutators

Molded Commutator manufacturing involves following stages -

.jpg)

.jpg)

Industrial Commutator manufacturing involves following stages -

Hard Drawn electrolytic (99.9%purity) or Silver Bearing Copper (0.1% Silver) is used. Silver bearing copper offer better heat resistance and bearing properties (Low wear of carbon brushes even at relatively higher temperatures.)

Separator Mica - For "H" Class insulation Alkyd Vinyl Bonded Mica & for "F" Class insulation Shellac Bonded Mica is recommended. We use Alkyd Vinyl Bonded Mica (finely ground resin bonded). For small Commutators paper Mica is used.

Mica "V" Cones - Mica "V" Cones are molded to drawing specifications from molding mica (Coarse Mica flakes with high bond content).

Steel Hubs / Spider - Steel Hubs / Spiders are either forged or steel castings depending on specifications. Machined to Specifications on CNC Machining Centers.

Glass Tapes - Glass tapes of 0.20 mm is used to prevent current tracking on Steel 'V' Ring. Glass tape is fixed with resins.

Copper lengths (normally multiple of segment length) received in trapezoidal form are cut to Segment Length (Segment length is Brush Length + Riser Width) with machining allowance.

Segment is punched into 'L' shaped & 'V' grooves (with machining allowance for plain & profile turning). Slots are milled on riser width for large Commutators with higher depths.

Separator Mica is punched as per Copper segment with additional length for Mica Projection on Riser side.

Commutator is assembled with alternate Copper & separator mica and checked for number of segments / skew etc.

Copper and mica segment assembly is then held in split ring with taper at both the ends with pressure plates and compressed under pre determine pressure are tighten with pre loaded torque wrench. This ensures radial movement of Copper and Separator Mica.

'V' Rings are profiled machined as per profile gauge in the assembled Commutator (normally 3 & 30 degree).

Commutator is assembled with Mica 'V' Cones and Steel 'V' Rings / Spider and is Seasoned using successive cycles of heating / rotating and tightening.

After seasoning Commutator is machined to final Brush / Riser diameters and then slotted (Riser).

Dimensional check using precision measuring instruments.

Spin Test - Commutator rotated at 1.5 to 2.5 times the rated R.P.M. on spin test machine to check for segment / bar rise .

Hipot Test - Bar-to-Bar and Bar-to-Ground Hipot test.

Insulation Resistance - Megger Test for Insulation Resistance.

*We are continiously researching and developing better process. Above Commutator Manufacturing process is only for information.

Molded Commutator manufacturing involves following stages -

Hard Drawn electrolytic (99.9%;purity) or Silver Bearing Copper (0.1% Silver) is used. Silver bearing copper offer better heat resistance and bearing properties (Low wear of carbon brushes even at relatively higher temperatures.)

Separator Mica - For "H" Class insulation Alkyd Vinyl Bonded Mica & for "F" Class insulation Shellac Bonded Mica is recommended. We use Alkyd Vinyl Bonded Mica (finely ground resin bonded).

Commutator molding material - Thermoset glass-reinforced DMC based on unsaturated polyester resin, this molding material possesses superior mechanical strengths, temperature resistance beyond 250°C, very high electrical insulating strengths, especially arc & track resistance and is fire retardant.

.jpg)

.jpg)

.jpg)

Copper lengths (normally multiple of segment length) received in trapezoidal form are cut to Segment Length (Segment length is Brush Length + Riser Width) with machining allowance.

Segment is punched into 'L' shaped & 'V' grooves (with machining allowance for plain & profile turning). Separator Mica is punched as per Copper segment with additional length for Mica Projection on Riser side.

Punched Copper Segments & mica segments are held secured in specially designed collet fixture. Assembly is retained in position by insulated steel rings at both ends.

Commutator is molded by heat gelation process in specially design hydraulic press / fixture.

Molded Commutator is then machined and tested as per customer's specifications.

.jpg)

Dimensional check using precision measuring instruments.

Spin test - Commutator is checked for segment / bar rise on diameter in spin test.

Hipot Test - Segment to Segment and Segment to Earth Hipot test.

Insulation Resistance - Megger Test for Insulation Resistance.